Protecting the planet with eco-friendly technologies and practices.

Bag filters

Efficient Particulate Control for Cleaner Boiler Operation

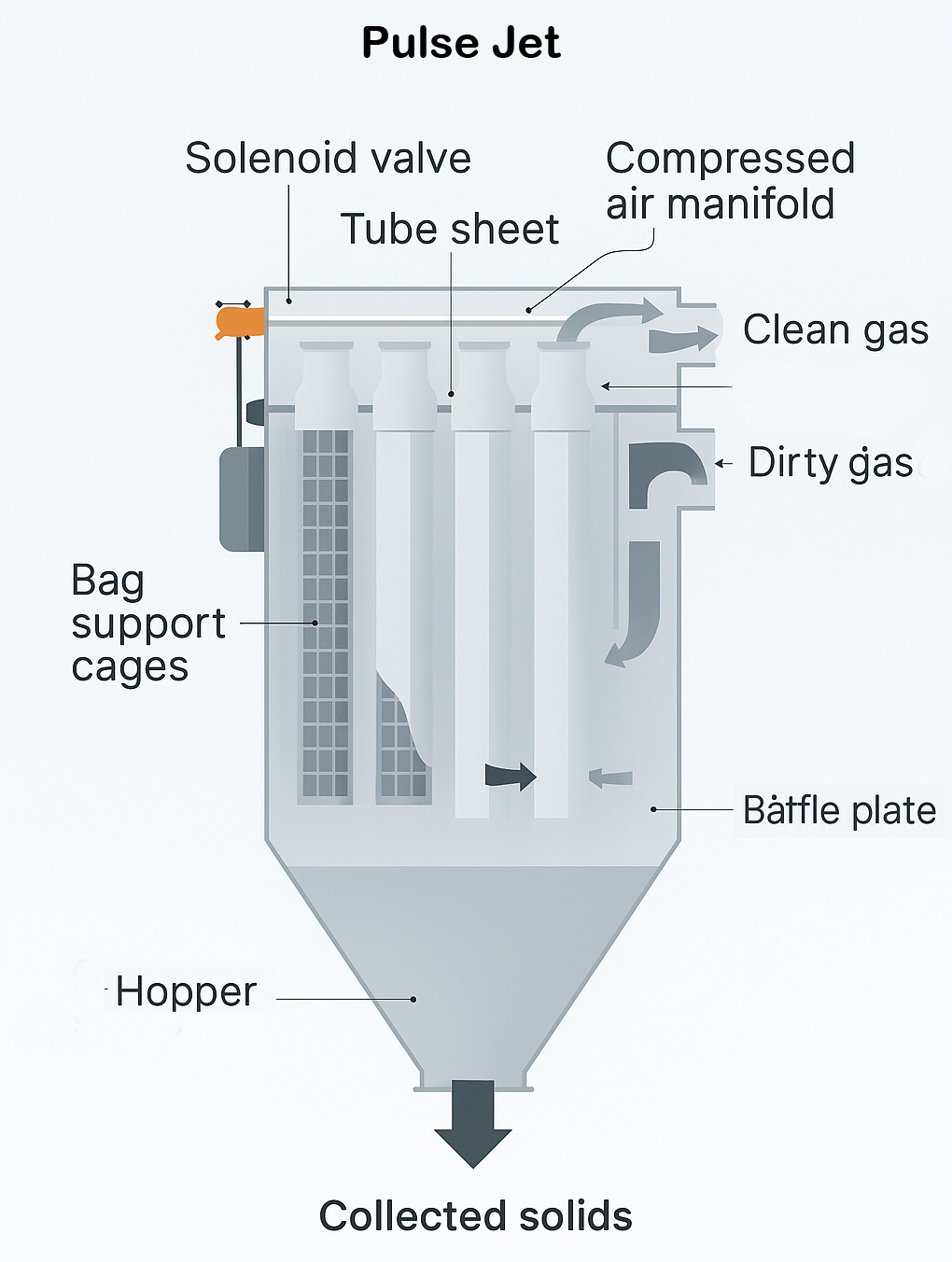

A Bag Filter, also known as a fabric filter or baghouse, is a vital pollution control device designed to capture particulate matter and dust from flue gases emitted by steam boilers. It ensures compliance with environmental regulations.

- High Filtration Efficiency: Captures up to 99.9% of fine particulate matter, including fly ash, soot, and unburnt carbon.

- Customizable Design: Available in various sizes and configurations to suit different boiler capacities and dust loads.

- Durable Filter Bags: Made from heat- and chemical-resistant fabrics such as PTFE, Nomex, or fiberglass to withstand high temperatures and corrosive gases.

- Low Maintenance: Automated cleaning mechanisms (pulse jet, reverse air, or shaker types) ensure longer bag life and reduced maintenance downtime.

- Compliance Ready: Designed to meet CPCB norms and other global emission standards.

Why Choose Us?

We provide engineered solutions tailored to your boiler system, offering installation, commissioning, and after-sales support. Whether you're retrofitting an old system or designing a new one, our bag filters are built for performance and longevity.

Single / Multicyclone Separators

Reliable Particulate Pre-Cleaning Solution

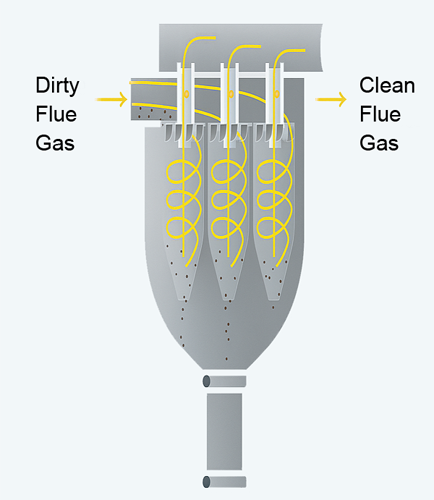

A Multi-Cyclone Separator is an efficient dust collection device used to pre-clean flue gases in biomass, coal, or solid fuel-fired steam boilers. It works by using centrifugal force to remove larger particulate matter from the gas stream before it enters fine filtration systems like bag filters.

- Multi-tube Design: Contains multiple small cyclone units in a single housing for high efficiency and compact structure.

- Efficient Particle Separation: Removes up to 85–90% of coarse dust (>20 microns) from flue gases.

- High-Temperature Resistant: Constructed using heat-resistant steel to handle flue gases up to 400°C.

- Low Maintenance: No moving parts and easy ash removal via rotary valves.

- Improves Downstream Equipment Life: Reduces dust load on bag filters or ESPs, lowering maintenance and increasing life span.

Wet Scrubbers

Effective Flue Gas Cleaning System for Emission Control

A Wet Scrubber is a pollution control device designed to remove fine dust particles, acidic gases (SOx), and other pollutants from the flue gas of coal, biomass, bagasse, or oil-fired steam boilers. It works by spraying water or a scrubbing liquid into the gas stream, effectively capturing contaminants through absorption and inertial impaction.

Other Products

- Spares - Bags, Cages, Cyclone, Pulse valves, Ash handling system

- Electrostatic Precipitators and ESP Internals