Explore our other strategic products

- Air & Flue Gas Dampers (Manual / Automated)

- Smart Storage System - Fuel Storage Management

- Soot Blowers for Boiler Cleaning

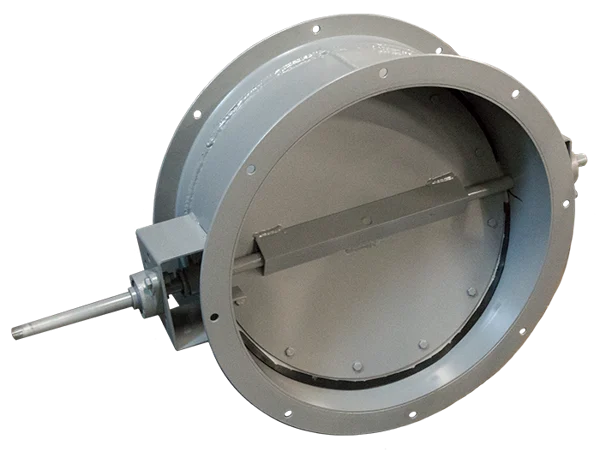

Product : Air & Flue Gas Dampers (Manual / Automated)

Precise control for efficient combustion. Optimize airflow, Maximize efficiency, Reduce operating costs. We offer high-performance Air and Flue Gas Dampers designed to regulate airflow and exhaust in boilers, heaters, and furnaces. Available in manual or automated models, our dampers improve combustion efficiency, reduce fuel consumption, and enhance system safety.

Key Features

- Manual or motorized (electric / pneumatic) operation

- Designs: Butterfly, Multi-louver, Guillotine, & Slide Gate

- High-temperature resistant materials (MS, SS, Alloy Steel)

- Airtight sealing and minimal pressure drop

- Compatible with PLC / SCADA / DCS systems

Applications

- Primary / secondary air control in boilers

- Flue gas modulation at ID fan or chimney

- Biomass, coal, oil, and gas-fired systems

- Heat recovery and pollution control setups

Product : Smart Storage System - Fuel Storage Management

A robust, large-scale solution for continuous fuel feeding in biomass and steam boiler systems. Our Smart Storage System with moving floor technology offers high-capacity, low-maintenance fuel management—without the need for tall structural silos.

Why Choose Our Moving Floor Storage System?

- High Capacity: Available in 100 m³, 150 m³, 200 m³, or customized as per requirement

- No Structural Silo Needed: Ground-level or underground installation—eliminates the need for expensive steel or RCC structures

- Minimal Manual Intervention: Requires fuel filling for only one shift—no manpower needed for the next two shifts

- Fully Automated: Seamlessly integrates with automatic fuel feeding systems for smooth and consistent operation

Ideal for biomass-fired boilers and industries looking to automate fuel logistics while saving on space, infrastructure cost, and labor.

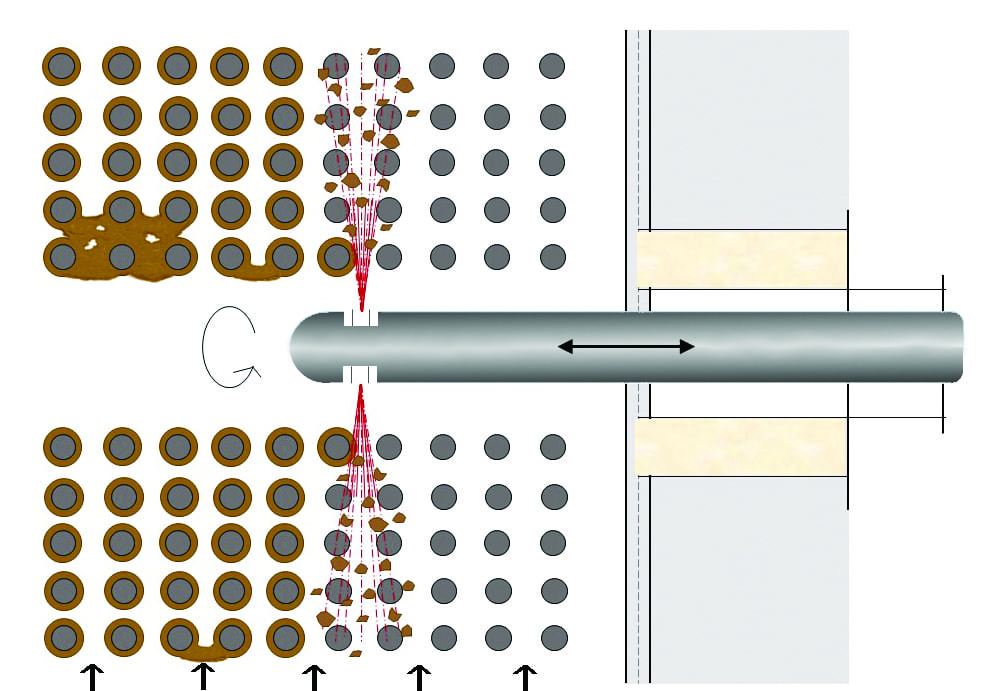

Product : Soot Blowers for Boiler Cleaning

Improve heat transfer. Maintain efficiency. Prolong equipment life. Soot blowers are essential devices used for cleaning heat transfer surfaces in boilers by removing ash, soot, and other combustion byproducts. Regular use of soot blowers maintains boiler efficiency, reduces fuel consumption, and prevents tube fouling or corrosion.

Our Soot Blower Solutions: We offer a range of manual and automatic soot blowers for various boiler types and capacities.

Key Features

- Available types: Rotary, Retractable, Wall Blowers, and Air/Steam Operated

- Removes soot and ash deposits from superheater, economizer, and boiler tubes

- Operated using compressed air or superheated steam

- Can be integrated into the boiler's automation / control system

- Suitable for biomass, coal, oil, and gas-fired boilers

- Reduces forced outages due to fouling or overheating

Benefits

- Enhances heat transfer and boiler efficiency

- Reduces fuel consumption and unburnt losses

- Minimizes manual cleaning efforts and downtime

- Extends the lifespan of boiler components

- Improves overall plant performance and reliability

Optimize boiler performance with effective soot blowing. Cleaner surfaces mean better combustion, lower emissions, and higher savings.